Why Corona Treatment is a Great Choice for Surface Finishing

Posted by Ritesh Patel on on 29th Nov 2021

How Do I Know Which Surface Finishing Method is Best for Me?

There are a large number of surface finishing options available from harsh, abrasive processes like sandblasting to more nondestructive techniques such as corona treatment. This is because there are a wide variety of materials and reasons why you might want to change the surface properties of a given material.

Despite this, there is no need to get overwhelmed by such a vast amount of choices. All you need to do in order to determine which method is best for you, is to consider the material you are working with and the reason why you need it treated.

In this article, we are going to discuss some of the different methods of surface finishing, compare them to corona treatment, and then weigh the pros and cons.

Why Corona Treatment?

Oftentimes, the reason why someone is looking to change the surface property of a material is because they want to make something stronger, more appealing, or easier to work with. However, some of these processes can be difficult, dangerous, and cause damage to the item that you are working on.

For instance, if your end goal is to print, apply paint, coat, or glue onto the surface of a material, you might look to common methods such as abrasive blasting, sanding, flame treatment, etc. However, these methods are destructive and might not work on certain types of materials that are more delicate such as plastic, cloth, or paper.

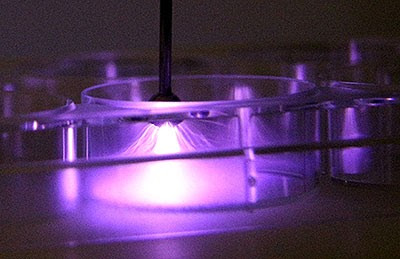

Corona treatment, also known as air plasma or plasma treatment, works by using high voltage power to emit a low-temperature plasma discharge that changes the surface energy of the material. This is a very safe and effective way to achieve the same desired result but quicker, safer, and with no risk of damaging the surface of the item that you are working on.

Some more specific examples of corona treatment applications include the production and treatment of contact lenses, microfluidic chips, pharmaceutical vials, petri dishes, medical tubing, and many more.

ETP manufactures the only handheld corona treatment device, called the BD-20AC. This device comes equipped with a variety of electrodes that allow for many different use cases - all without causing damage to the material that is being treated.

The 3 in. Wire Field-Effect Electrode (Model 13811) is a very well-rounded electrode used for treating both flat and curved surfaces. The Round Electrode (Model 12811) is ideal for treating primarily flat surfaces while the Spring Electrode Tip (Model 12201) is best suited for treating cavities and the inner diameters of tubes. To learn more about our corona treater, its electrodes, and associated tools check out our blog, ”Getting the Most out of Your Corona Treater with Tools & Accessories.”

Although corona treatment can improve wettability, printing effectiveness, and adhesiveness - the surface of the material that was treated looks the exact same because the results of corona treatment are invisible to the naked eye.

This is why corona treatment is, more often than not, a great alternative to achieve the same desired result that other more destructive methods can yield.

Final Thoughts

At the end of the day, deciding the best surface finishing method really depends on the materials you are working with. However, the last thing you want to do is ruin your workpiece by going with a process that is too harsh or abrasive. Corona treatment is a lesser-known method, but a lot of times it can be safer and more effective - so it certainly should not be overlooked!

To learn more about corona treatment and how it works, please read our blog titled, “What is Corona Treatment and How it Can Help You”. To learn about different use cases and industries where this technology is typically used, check out our Applications page.