What is Corona Treatment and how it can help you.

Posted by Ajay Gupta on on 29th Nov 2021

Have you ever had an issue adhering, gluing or bonding to plastic? Have you tried a number of solutions and methods but haven’t been successful in manipulating the surface tension, of your material, in order to proceed with applications such as laminating, printing or painting.

Well there is good news, corona treatment may be a possible solution to your problem. Here you will be able to obtain a basic understanding of corona surface treatment, how it works and if it’s right for you.

What is Corona Treatment?

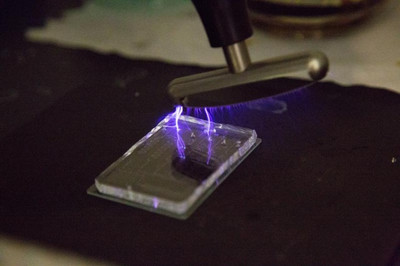

Corona Treatment is a technique in which high voltage and high frequency are leveraged to create, a corona discharge, to manipulate the inherent surface energy, and change the intermolecurlar bonds that occur when a surface is created, of various materials. The corona discharge is created when the high voltage and frequency electrical potential is applied to an electrode (ex. wire electrode or spring tip electrode). The corona discharge ionizes nearby atmosphere and when this is applied directly to the material it increases the surface tension of the material.

How does Corona Treatment Work?

As mentioned above corona treatment is the product of corona discharge generated by a high voltage / frequency corona treater ionizing the nearby atmosphere. When this mixture is applied to plastics, such as polyethylene or polypropylene, the surface energy or dyne level of the plastic is increased because the corona discharge is drawn to the material. The corona discharge breaks the molecular bond of the material and once the bonds are broken the particles are free to attach to other particles. The result is increased surface tension of the material and improved bonding capabilities to coatings, paint, ink adhesives etc.

Is Corona Treatment right for me?

Corona Treatment has been found to be a very effective process on many materials, components, for various applications in a number of industries and settings - some of the most common ones are listed in the chart below:

|

Materials Treated |

Components | Applications | Industries |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|||

|

|||

|

A number of variables can impact corona treatment and the impact it may have on an application. Therefore, it is important to understand the different factors which will impact the overall results of corona surface treatment. The following variables along with any specific requirements, need to be addressed when considering corona treatment

- Treatment Time

- Power

- Distance between electrode & material

- Electrode size and shape

- Surface area being treated

- Type of material being treated

- Application (ie Coating vs. Paint)

- Output requirements & speed

After considering the above, it has been found best to test treat a sample of product to undersand the watt density required to achieve the desired outcome. This is measured in Watts/Area/Minutes. Watt density takes into account the amount of power being applied (watts), the time it is being applied (minute) and the amount of material it is being applied to (Area). Once the watt density is known to get a particular material to a certain dyne level, it can be used to predict the results if any of the parameters change such as line speed.

This way one can be assured, prior to purchasing a unit, that corona treatment will achieve the desired results.

All in all corona treatment is a great option to improve one’s ability to bond to various polymers. Combining high voltage and frequency output, corona treaters such as the BD-20AC or BD-80C, are able to create a corona discharge to manipulate the surface tension of polymers increasing their ability to bond to inks, adhesives, coatings and paint.

If you are considering corona surface treatment and have additional questions Electro-Technic Products is more than happy to assist you. ETP has 25 + years of experience in corona surface treatment and our corona treaters and services are used throughout various industries in lab and manufacturing settings. Please feel free to contact us at info@electrotechnicproducts.com or (773) 561 – 2349. If you want to learn more, feel free to click below to obtain a deeper understanding of corona treatment can help you!

Download our Corona Treatment and PDMS Bonding White Paper

Topics: Corona Treatment